“It’s always better to do it on your terms instead of life’s terms” is a favorite saying I learned from my wife. It is usually shared with one of our kids when there is something that they are going to have to do at some point in time. It is also sometimes mentioned that said kid’s favorite day appears to be “tomorrow.” As in, “I’ll get to it tomorrow.”

I believe all of us suffer from the “tomorrow” mindset from time to time. Yet the fact remains that while certain things are inevitable, it is always better to do things on your timing where you are in control of the event. If you fly the same plane long enough, replacing or overhauling your engine falls into that category.

We bought our plane in December 2016, the engine had 1,415 hours SMOH (Since Major Overhaul). It had flown regularly so I had reason to believe it would make it to TBO (Time Between Overhaul) which is 2.000 hours, but that still meant that an engine replacement/overhaul wasn’t too many years in the future. Averaging 130 hours a year we soon passed TBO, and the engine was still running well, compressions in the 78-80/80 range, not making metal and not using any more oil than normal.

The Plan

What follows is my thought process on the engine replacement and how it has played out.

In 2023 as we approached 2,200 hours SMOH, I started making plans to do the engine on my terms. A friend recently had 6 months downtime when her engine was sent out for overhaul and heard others with similar delays. Shops are just backed up and seem to be running into parts delays. When I go more than a couple weeks without flying I start jonesing to be up in the air,. Six months without flying? I most likely wouldn’t be much fun to be around…

My plan was to buy a core or old runout engine, have it overhauled, and then my AP/IA could swap it out with minimal downtime. I started searching in vain for an O-360-A1D to serve as the replacement engine. After a couple months I gave up on that plan and placed an order with Airpower for a Factory Rebuilt with a 12-14 month lead time. I reasoned that at the pace I was flying, 12-14 months would put me around 2,300+ SMOH when the engine was ready. It was more expensive than the overhaul route, but I thought it would be worth it for the Factory Rebuilt and knowing when it would be ready.

First Delay

One year later I checked in with Airpower to see if the 12–14-month timeline was still accurate. I was disappointed when they emailed back that the new anticipated date was 1/31/2025, making it 19 months from when the order was replaced. Concerned that additional delays could push it out even further I began the search anew for a core that could be overhauled. While 2,300 SMOH on my engine sounded reasonable, the further I pushed it to 2,400 or 2,500+ I knew I would be coming closer to “life’s terms.”

Unlike my search a year prior, I found a core at Airmark Engines in Florida and received a quote along with a 7-9 week turn to complete the overhaul. Airmark is not one of the “big names” I have heard about over the years, so I did a little research on the company looking for reviews. They overhaul 300+ engines a year and have been in business since 1975. The search turned up a few good reviews and no bad reviews. I decided if I couldn’t find a bad review about a company that overhauls 300+ engines a year and has been in business for almost 50 years, that is a good sign. I placed the order with Airmark and canceled the order with Airpower.

A short 5 weeks later I received an email that the engine was ready. I reached out to my AP/IA to get on his schedule and arranged for the engine to be shipped to him. So far everything had been going according to my terms. I had a few trips coming up, like the Mother’s Day flight I wrote about last month, and the plan was for it to go in his shop on May 20th or shortly thereafter.

Second Delay

May 20th came and went. He was still finishing up an engine replacement ahead of my plane so I went flying on the 27th. After landing I sent him a text that I was going to pull the cowl and began removing adel clamps and hardware. Just before removing the lower cowl, I checked my phone to see he had texted me back (almost immediately). He said he knows it’s a pain to remove and I’m trying to help, but it’s easier for them to remove everything to see how it is all routed. I told him what I had already done to that point, kicked myself for missing his text, and headed home.

Two weeks later he was still wrestling with the engine swap that was in front of me which had turned into a nightmare. It’s one of those jobs that when we refer to them at the dealerships we say, “you’re now married to it.” Those are the ones where nothing seems to be going right, and every time you fix one issue three more seem to pop up. While I was frustrated at the delay, I felt for him having witnessed it before on many occasions.

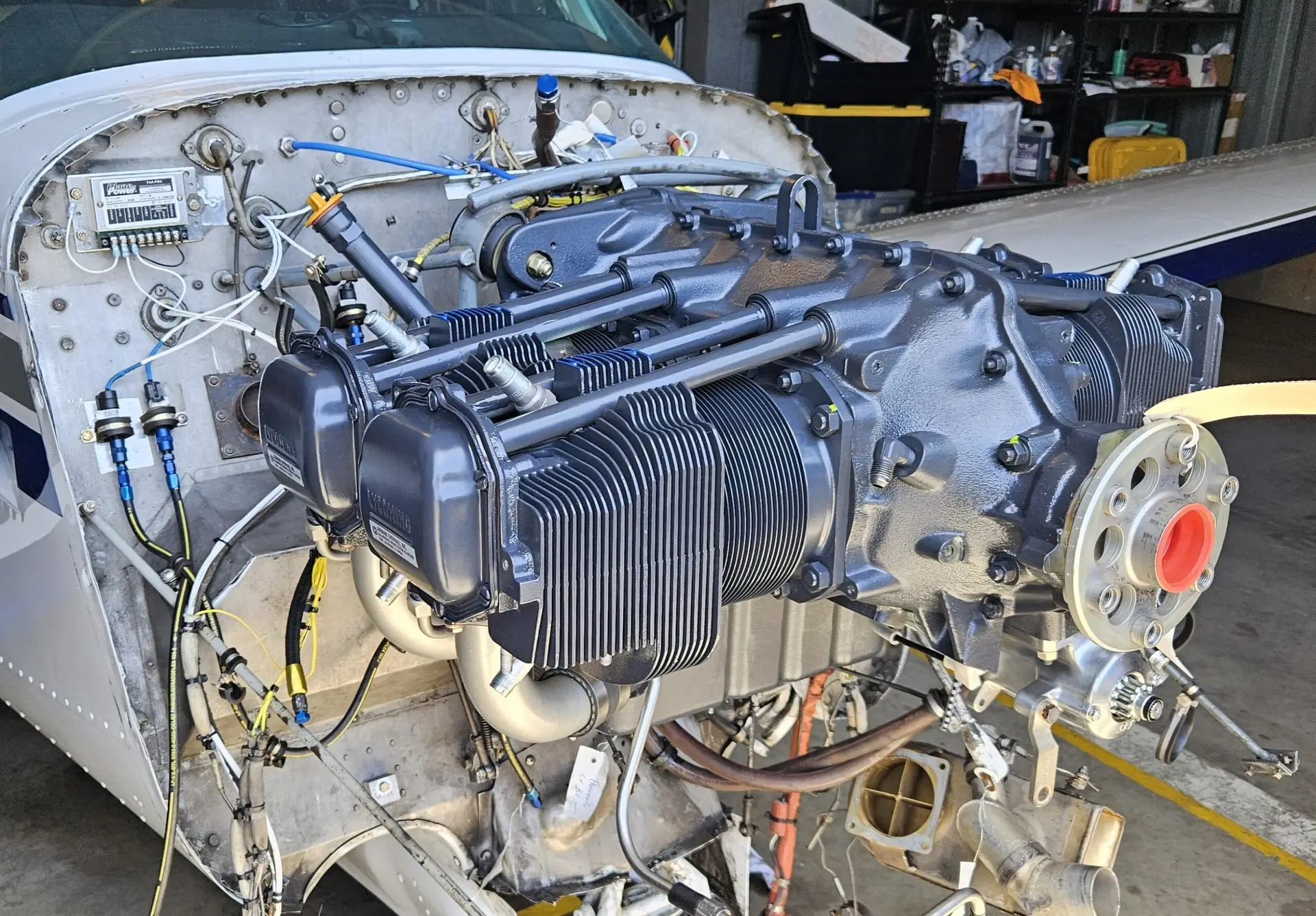

Without further unforeseen issues he would be starting my plane the next week, so I told him I was going to put everything back together and go flying that weekend. When I was done, I would leave it all as is for him and his guys to pull apart. There were more delays, but they did finally get to my plane and started making short work of the task at hand. A day and a half into the job the new engine was hung, and they were working on transferring fittings, the engine heater, surefly mag, and other items from the old engine to the new one.

The prop, governor, and oil cooler had been sent out for overhaul, and everything he had control of was getting completed in a very timely manner. I even had hopes of getting a few break-in flights completed and going to the fly-in at Paso Robles at the end of June.

Third Delay

The prop came back from overhaul, and I spoke with the shop doing the governor to pay that invoice and get the ETA for its return. Everything was looking good. But then life stepped in with a curveball and dashed my hopes. My mechanic asked if I had heard yet from the shop doing the oil cooler. They were supposed to call me for payment when they were done. I hadn’t, so I gave them a call.

UPS had picked up the shipment, but somewhere en route it was delayed and took a week to get there. It would be another week to ten days before they would have it complete, putting me into the first week in July and missing the fly-in.

Hoses had all been replaced a couple years prior and other necessary parts like the engine mounts/bolts, gaskets for powerflow exhaust, belt, etc. were all acquired ahead of time. Everything that could be done on my end to minimize downtime had been done. But, like many things in life despite your best efforts, life gives you a little something just to remind you that you’re not completely in charge.

The job should still be done in three weeks, which was the original time he estimated for the job. Without the oil cooler hold up it would have been completed in just two weeks. We’ll call this one a combination of my terms and life’s terms, exponentially better than only life’s terms.

Unless there are further unforeseen delays (I just gave a couple quick knocks on the wood table next to me as I sit on the couch typing), I will have stories to tell about the engine break in process next month. Until then, safe flying, and do as much as you can on your terms.